|

|

|

|

Popular Alternative Choice

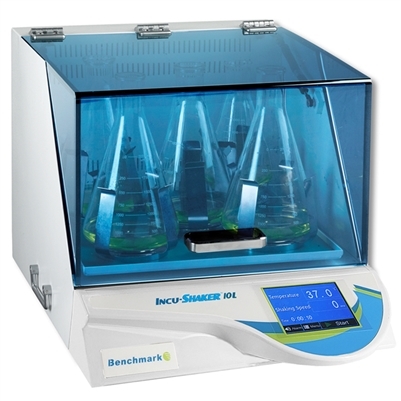

Benchmark H2010 Incu-Shaker 10L Shaking Incubator

- Incu-Shaker 10L: Heavy-duty with precision touch screen controls.

- Features: 30 to 300 RPM speed, 0.1°C temp increments, MAGic Clamp accessory.

- Specs: 19mm orbit, up to 48 hours timer, ±0.1C temperature accuracy.

- Included: 18"x18" Rubber Mat, MAGic Clamp option, 2 Year Warranty.

Go to Product Details

Brand New!

VWR 1575 Incubator Shaker

Temperature Range

Ambient ± 1°C to 37°C

Speed Range

30 to 400 rpm

Interior Dimensions

19 x 19.25 x 23.5 in

- Accessory outlet to provide power for equipment such as magnetic stirrers, and rockers.

- Microprocessor control, enabling precise temperature adjustments within 0.1°C, essential for sensitive and accurate experiments.

- High-performance brushless DC motor which allows for speeds up to 400 RPM.

- Noncontact, low watt density nichrome heating element, designed for maximum service life and consistent performance.

The VWR 1575 is a benchtop incubator shaker

with microprocessor control, allowing for precise temperature adjustment within

0.1°C. The VWR 1575's high-performance brushless DC motor develops speeds of 30

to 400 rpm with smooth rotation. The noncontact, low watt density nichrome

heating element provides maximum service life.

The VWR 1575 is ideal for genetic research, cell aeration,

bacterial aeration, metabolism studies, and tissue culture studies.

All of our equipment is fully tested to perform at factory specifications before being shipped.

The VWR 1575 Incubator Shaker includes:

- > Platform

- > Shelf

- > NIST Calibration and Preventative Maintenance Report

- > Power Cord

- > Operator's Manual

- > Full 180 Day Parts and Labor Warranty

VWR 1575 Incubator Shaker Specifications

|

Temperature Range

|

Ambient ± 1°C to 37°C

|

|

Temperature Uniformity

|

± 0.5°C

|

|

Temperature Sensitivity

|

0.1C

|

|

Speed

|

30 to 400 rpm

|

|

Volume

|

167 L (5.8 cu. ft.)

|

|

Orbit Diameter

|

12, 19, or 25 mm

|

|

Max Sample Weight

|

10 kg (22 lbs)

|

|

Shelf Dimensions

|

47 x 47 cm (18.5 x 18.5 in)

|

|

Interior Dimensions

|

48 x 51 x 66 cm (19 x 19.25 x 23.5 in)

|

|

Exterior Dimensions

|

58 x 69 x 105 cm (23.5 x 28.5 x 40.5 in)

|

|

Electrical

|

110-120 V, 50/60 Hz

|

VWR 1575 Manual

Click Here to View all the Technical Specs for the VWR 1575 Click Here to View all the Technical Specs for the VWR 1575

- Examine the chamber glass for cracks or chips, replacing it as needed to maintain structural integrity.

- Inspect door seals for signs of wear or damage, replacing them to ensure a tight seal.

- Check the display for brightness and clarity, replacing any dim or dead pixels to maintain optimal visibility.

- Test all buttons to confirm full functionality and consistent responsiveness.

- Replace all platform assembly bearings to ensure smooth and reliable motion.

- Inspect the drive belt for wear, replacing it if torn or cracked to maintain performance.

- Examine all wiring for frays, tears, or breakages, addressing any issues for electrical safety.

- Verify each PCB test point, replacing any malfunctioning components to ensure system reliability.

- Check drive belt tension to confirm correct alignment and function.

- Confirm the compressor’s operation, cleaning condenser filter and fins for efficient cooling.

- Calibrate internal temperature accuracy using an NIST-traceable temperature probe.

- Measure and calibrate platform RPMs with an NIST-traceable tachometer to ensure precision.

- Conduct a final cosmetic inspection to verify all surfaces meet appearance standards.

Technician Inspection and Recertification Checklist

The Following Checklist Is to Be Performed on All Incoming and Outgoing Equipment

| Task |

Completed? |

Remarks? |

| Examine chamber glass for cracks or chips, replace as needed | Completed | |

| Inspect door seals for wear, replace to ensure tight seal | Completed | |

| Check display brightness, replace dim or dead pixels | Completed | |

| Test all buttons for full functionality and responsiveness | Completed | |

| Replace platform assembly bearings for reliable motion | Completed | |

| Inspect drive belt for wear, replace if torn or cracked | Completed | |

| Examine wiring for frays or breakages, repair as needed | Completed | |

| Verify PCB test points, replace faulty components | Completed | |

| Check drive belt tension for proper alignment | Completed | |

| Confirm compressor functionality, clean filter and fins | Completed | |

| Calibrate internal temperature with NIST probe | Completed | |

| Calibrate platform RPM with NIST-traceable tachometer | Completed | |

| Conduct cosmetic inspection for appearance standards | Completed | |

To View More of Our Recertification Protocol Click Here

|

|

|

|

|

|

|