|

|

|

|

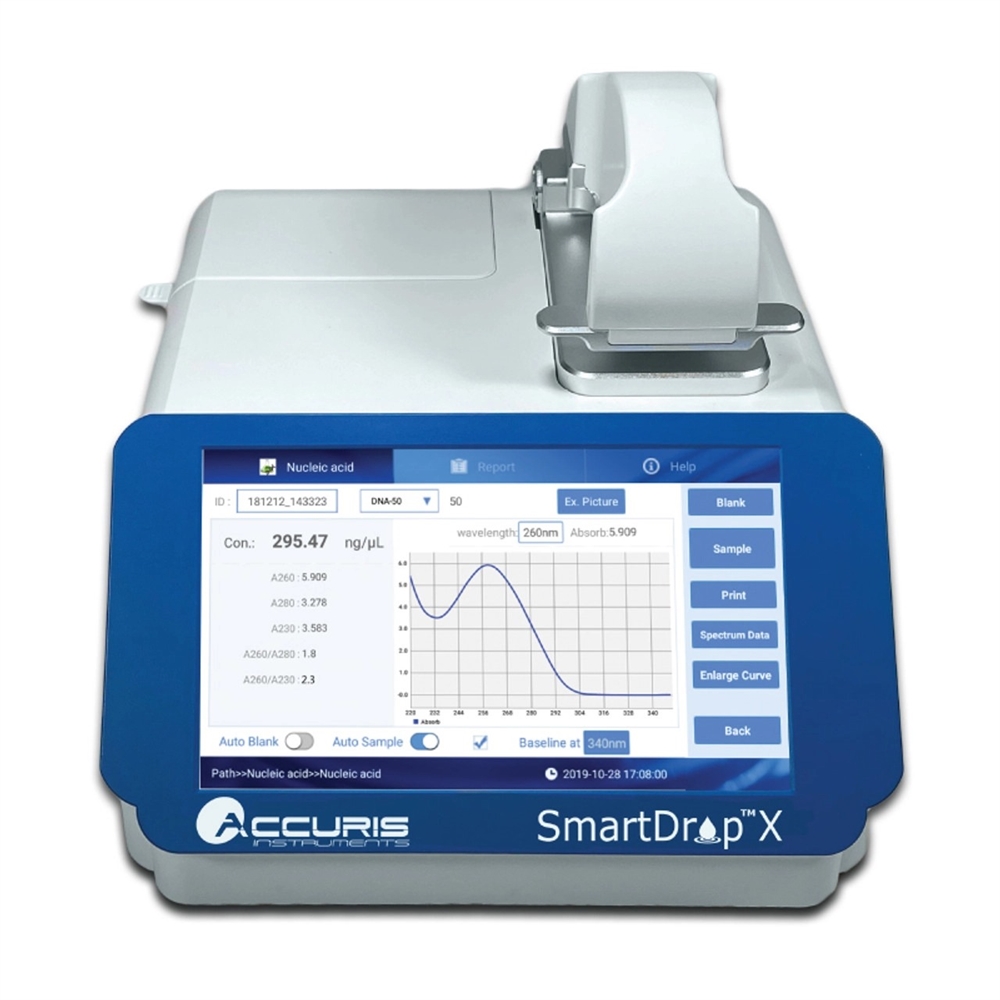

Popular Alternative Choice

Accuris SmartDrop X Nano Spectrophotometer, 115V

- UV-Vis spectrophotometer with 200-800nm range in 1 nm steps.

- Requires 0.5-2.0µl sample; full spectrum analysis in ~6 seconds.

- Detects up to 4,500 ng/µl dsDNA; long-life Xenon lamp source.

- 7-inch touch screen display; USB data port for easy exporting.

Go to Product Details

Brand New!

Thermo Scientific NanoDrop 2000c Spectrophotometer

Absorbance Range

Pedestal: 0-300

- High precision and reproducibility measures up to 2 µl samples with exceptional accuracy.

- Full-spectrum spectrophotometer delivers analysis over a wide range of wavelengths.

- Surface tension technology for measuring of highly concentrated samples.

- Samples ID and type selection facilitate easy identification and categorization of samples.

- Adjusts absorbance readings at specific correction wavelengths.

The Thermo Scientific NanoDrop 2000c is a full-spectrum spectrophotometer that measures up to 2 ul samples with high accuracy and reproducibility.

This system offers the convenience of both the NanoDrop patented sample retention technology and a traditional cuvette for sample measurements. Surface tension technology keeps the sample in place with two optical filters to enable the measurement of very highly concentrated samples without having to dilute. The 2000c can measure high-concentration samples without dilution that many standard cuvette spectrophotometers cannot, measuring up to 200 times more concentrated solutions.

Applications include measuring: Nucleic Acid Quantification, DNA Quantification, RNA Quantification, and Protein Quantification.

All of our equipment is fully tested to perform at factory

specifications before being shipped.

The Thermo Scientific NanoDrop 2000c Spectrophotometer includes:

- > Windows 10 Pro Data Station with Nanodrop Software Preloaded

- > CF-1 Calibration Report

- > Power Cord

- > Full 180 Day Parts and Labor Warranty

Thermo Scientific NanoDrop 2000c Spectrophotometer Specifications

|

Absorbance Accuracy

|

3% (at 0.74 Abs at 350nm)

|

|

Absorbance Range

|

Pedestal: 0-300 ABS Cuvette: 0 - 1.5 ABS

|

|

Accuracy

|

0.002

|

|

Accuracy (Absorption)

|

3% at (0.74 at 350nm)

|

|

Compatibility

|

Microsoft Windows XP (32-bit) w/Service Pack (SP) 2 or later,

Vista (32-bit), Windows 7 (32 bit and 64 bit), Windows 10 (64 bit)

|

|

Concentration

|

2ng/l-15,000ng/l (dsDNA) ng/l

|

|

Detection Limits

|

Pedestal: 2ng/L (dsDNA), 0.10mg/mL (BSA) Cuvette: 0.4ng/L (dsDNA),

0.01 mg/mL (BSA)

|

|

Detection Range

|

Pedestal: 2-15,000ng/L (dsDNA) , 0.10 - 400mg/mL (BSA)

|

|

Detector Type

|

2048-element linear silicon CCD array

|

|

Dimensions

|

14 x 20cm

|

|

Heating Range

|

37; 0.5C

|

|

Lamp

|

Xenon Flash

|

|

Measurement Time

|

<3 sec.

|

|

No. of Samples

|

1

|

|

Pathlength (Metric)

|

10; 5; 2; 1mm

|

|

Power Consumption

|

12VDC, 5W

|

|

Sample Volume (Metric)

|

1000, 0.5-2.0L

|

|

Spectral Resolution

|

=1.8nm (FWHM at Hg 253.7)

|

|

System Requirements

|

Microsoft Windows 7 Professional (32-bit and 64-bit), Windows 8 (32-

and 64-bit), and Windows 10 Pro (64-bit)

|

|

Wavelength Accuracy

|

1nm

|

|

Wavelength Range

|

190-840nm

|

- Confirm the power supply and PCB output correct, stable voltages across all required connections

- Inspect the display for any dim or dead pixels; replace affected components to maintain full visual clarity and operational accuracy

- Verify full functionality of all buttons, ensuring precise and responsive input control

- Check the XY assembly for proper movement and alignment; thoroughly clean all railings, removing any debris or contaminants

- Confirm stable software communication and connection between the instrument and PC, addressing any connectivity issues

- Inspect and clean or replace all filters as required to ensure optimal airflow and performance

- Examine internal wiring and electrical connections for any breaks, disconnections, or tears; replace or secure any compromised wiring

- Test the lamp’s full functionality, replacing it if any performance issues, dimming, or faults are detected

- Execute the necessary validation protocol, documenting completion with a date on a calibration/verification certificate

- Perform and verify appropriate updates to the PC operating system for compatibility and security

- Conduct a thorough cosmetic inspection, ensuring all external components meet quality and aesthetic standards

Technician Inspection and Recertification Checklist: Instruments

The Following Checklist Is to Be Performed on All Incoming and Outgoing Pieces of Equipment

|

Task

|

Completed?

|

Remarks?

|

|

Confirm stable, correct voltage outputs from power supply and PCB

|

Completed

|

|

|

Inspect display for dim or dead pixels; replace as needed

|

Completed

|

|

|

Verify functionality of all buttons for precise, responsive control

|

Completed

|

|

|

Check XY assembly for proper movement; clean railings to remove debris

|

Completed

|

|

|

Confirm stable software communication between instrument and PC

|

Completed

|

|

|

Inspect and clean or replace filters to maintain optimal performance

|

Completed

|

|

|

Examine internal wiring for damage; replace or secure compromised connections

|

Completed

|

|

|

Test lamp functionality; replace if dimming or faults are detected

|

Completed

|

|

|

Execute validation protocol and document on calibration/verification certificate

|

Completed

|

|

|

Update PC operating system for compatibility and security

|

Completed

|

|

|

Conduct cosmetic inspection to ensure quality of external components

|

Completed

|

|

To View More of Our Recertification Protocol Click Here

|

|

|

|

|

|

|