|

|

|

|

Popular Alternative Choice

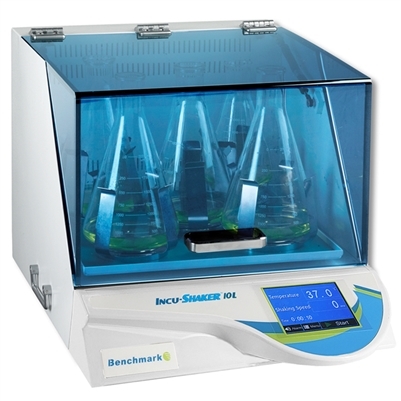

Benchmark H2010 Incu-Shaker 10L Shaking Incubator

- Exceptional temperature precision with proprietary heat distribution.

- Advanced brushless induction drive for continuous heavy-duty use.

- Touch screen control for time, speed, and temperature settings.

- Optional MAGic Clamp Platform for easy flask exchanges via magnetic attachment.

Go to Product Details

No Lead Time!

New Brunswick Innova 40R Refrigerated Incubator Shaker

The New Brunswick Innova 40R Refrigerated Incubator Shaker is a benchtop orbital incubator shaker that combines a triple eccentric counterbalanced drive mechanism with precision temperature control all in one compact unit. A speed range of 25 to 500 RPM is utilized with a wide temperature range of Ambient -15°C to 80°C, with a minimum of 4°C. The self-supporting transparent lid allows samples to be in view at all times, and with the ability to shake flasks up to 3L, the 40R is the perfect incubator shaker to begin working on small-scale projects while increasing volume or throughput.

The refrigeration system in the Innova 40R is a variable-capacity system designed with self-checks to maintain the setpoint, balance pressure within the system, and to keep the evaporator from freezing. This M1299-0094 model also features an orbit size of 2.5 cm (1 in).

The New Brunswick Innova 40R Refrigerated Incubator Shaker may also be operated in the following ways: continuously at a set speed and temperature until the user stops the device, timed mode at a set speed, time, and temperature, through the shaker's programmable controller for setting up multi-step programs, or lastly through a computer utilizing the RS-232 interface. Common applications for the Innova 40R include bacterial, insect, yeast, and plant cells growth, screen culture media, as growing seed cultures ,and more.

All of our equipment is fully tested to perform at factory

specifications before being shipped.

The New Brunswick Innova 40R Refrigerated Incubator Shaker includes:

- > 18" x 18" Platform

- > NIST Calibration and Preventative Maintenance Report

- > Power Cord

- > Operator's Manual

- > Full 180 Day Parts and Labor Warranty

New Brunswick Innova 40R Refrigerated Incubator Shaker Specifications

|

Speed Range

|

25 to 500 RPM

|

|

Speed Control Accuracy

|

± 1 RPM

|

|

Temperature Range

|

Ambient -15°C to 80°C (Minimum 4C)

|

|

Temperature Uniformity

|

± 0.25°C at 37°C

|

|

Timer

|

0.01 to 99.59 hours, continuous

|

|

Program Modes

|

Constant speed and temperature, multi-steps, and RS-232 communications

|

|

Orbit Size

|

2.5 cm (1 in)

|

|

Platform Size

|

18 x 18 in (46 x 46 cm)

|

|

Chamber Dimensions (W x D x H)

|

20.3 x 21.5 x 14 in (51.4 x 54.4 x 35.6 cm)

|

|

Overall Dimensions (W x D x H)

|

22 x 30 x 24 in (55.9 x 76.2 x 61 cm)

|

|

Weight

|

175 lb (79 kg)

|

|

Electrical Requirements

|

120V, 60Hz, 1Ph, 1500VA

|

New Brunswick Innova 40R Refrigerated Incubator Shaker Manual

Click Here to View the Technical Specs for the Innova 40R Refrigerated Incubator Shaker Click Here to View the Technical Specs for the Innova 40R Refrigerated Incubator Shaker

- Examine the chamber glass for cracks or chips, replacing it as needed to maintain structural integrity.

- Inspect door seals for signs of wear or damage, replacing them to ensure a tight seal.

- Check the display for brightness and clarity, replacing any dim or dead pixels to maintain optimal visibility.

- Test all buttons to confirm full functionality and consistent responsiveness.

- Replace all platform assembly bearings to ensure smooth and reliable motion.

- Inspect the drive belt for wear, replacing it if torn or cracked to maintain performance.

- Examine all wiring for frays, tears, or breakages, addressing any issues for electrical safety.

- Verify each PCB test point, replacing any malfunctioning components to ensure system reliability.

- Check drive belt tension to confirm correct alignment and function.

- Confirm the compressor’s operation, cleaning condenser filter and fins for efficient cooling.

- Calibrate internal temperature accuracy using an NIST-traceable temperature probe.

- Measure and calibrate platform RPMs with an NIST-traceable tachometer to ensure precision.

- Conduct a final cosmetic inspection to verify all surfaces meet appearance standards.

Technician Inspection and Recertification Checklist

The Following Checklist Is to Be Performed on All Incoming and Outgoing Equipment

| Task |

Completed? |

Remarks? |

| Examine chamber glass for cracks or chips, replace as needed | Completed | |

| Inspect door seals for wear, replace to ensure tight seal | Completed | |

| Check display brightness, replace dim or dead pixels | Completed | |

| Test all buttons for full functionality and responsiveness | Completed | |

| Replace platform assembly bearings for reliable motion | Completed | |

| Inspect drive belt for wear, replace if torn or cracked | Completed | |

| Examine wiring for frays or breakages, repair as needed | Completed | |

| Verify PCB test points, replace faulty components | Completed | |

| Check drive belt tension for proper alignment | Completed | |

| Confirm compressor functionality, clean filter and fins | Completed | |

| Calibrate internal temperature with NIST probe | Completed | |

| Calibrate platform RPM with NIST-traceable tachometer | Completed | |

| Conduct cosmetic inspection for appearance standards | Completed | |

To View More of Our Recertification Protocol Click Here

|

|

|

|

|

|

|