|

|

|

|

Popular Alternative Choice

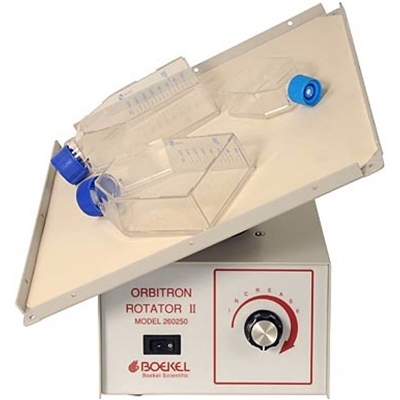

Boekel Scientific 260250 Orbitron Rotator II, 115V

- Adjustable speed: 6-23 orbits/min

- Gentle, low foaming agitation

- Operates from 4ºC to 40ºC

- Comes with two non-slip mats

Go to Product Details

Brand New & Ships in 2 to 3 Business Days!

Boekel Orbitron Rotator II Model 260250

The Boekel Scientific Orbitron II, adjustable speed nutating mixer, is excellent for any application requiring a gentle, low foaming lab agitation. The unit has adjustable speed from 6 to 23 orbits/min, a small footprint, fixed position platform, and can be used in an incubator or cold room. The tilt angle is fixed at 23° and the unit can handle a load limit up to 2.25 lbs.

The Boekel Orbitron Rotator II Model 260250 includes:

- > Calibration Report

- > Power Cord

- > Full 180 Day Parts and Labor Warranty

Boekel Orbitron Rotator II Model 260250 Specifications

|

Temperature Range

|

4°C to 40°C

|

|

Adjustable Speed

|

6 to 23 orbits/min

|

|

Fixed Tilt Angle

|

23°

|

|

Load Limit

|

2.25 lbs.

|

|

Electrical

|

115V, 6W, 0.5A

|

|

Dimensions (W x D x H)

|

12" x 12" x 10" (30.5 x 30.5 x 25.4 cm)

|

|

Weight

|

10 lbs.

|

Boekel Orbitron Rotator II Manual

Click Here to View the Technical Specs for the Boekel Orbitron Rotator II Click Here to View the Technical Specs for the Boekel Orbitron Rotator II

Boekel Orbitron Rotator - Marshall Scientific

- Validate that the power supply and PCB deliver stable, correct voltage outputs across all necessary connections, ensuring reliable operation

- Thoroughly inspect the display for any dim, flickering, or dead pixels; replace affected elements to maintain full readability and operational clarity

- Test the full range of button functionality, confirming responsive, accurate input recognition across all settings

- Conduct a detailed inspection of bearings and bearing housing, identifying any worn or damaged bearings, and replace as needed to prevent operational disruption

- Examine the drive belt for signs of cracking, fraying, or material breakdown; replace as required to ensure sustained performance

- Measure and adjust motor drive belt tension to optimal specifications, securing reliable and efficient power transmission

- Verify accuracy of the onboard timer, confirming proper functionality and replacing if it deviates from expected performance

- Calibrate shaker rotation speed with a NIST-traceable tachometer, validating precision within specified operational limits

- Run the shaker continuously for an 8-12 hour testing period, closely observing the shaking platform for smooth, consistent motion, while monitoring for any error indicators such as knocking, skipping, or unusual vibrations

- Perform a comprehensive cosmetic inspection to confirm the device’s exterior meets aesthetic and quality standards, free from visible damage or wear

Technician Inspection and Recertification Checklist: Shakers

The Following Checklist Is to Be Performed on All Incoming and Outgoing Pieces of Equipment

|

Task

|

Completed?

|

Remarks?

|

|

Validate stable, correct voltage outputs from power supply and PCB

|

Completed

|

|

|

Inspect display for dim, flickering, or dead pixels; replace as needed

|

Completed

|

|

|

Test button functionality for responsiveness and accuracy across all settings

|

Completed

|

|

|

Inspect bearings and housing for wear; replace as needed to prevent disruption

|

Completed

|

|

|

Examine drive belt for cracking, fraying, or material breakdown; replace as required

|

Completed

|

|

|

Measure and adjust motor drive belt tension to optimal specifications

|

Completed

|

|

|

Verify onboard timer accuracy; replace if it deviates from expected performance

|

Completed

|

|

|

Calibrate shaker rotation speed using a NIST-traceable tachometer

|

Completed

|

|

|

Run 8-12 hour continuous test; observe platform for smooth, consistent motion

|

Completed

|

|

|

Perform comprehensive cosmetic inspection for quality standards compliance

|

Completed

|

|

To View More of Our Recertification Protocol Click Here

|

|

|

|

|

|

|